Angle edge and stair nosing profiles

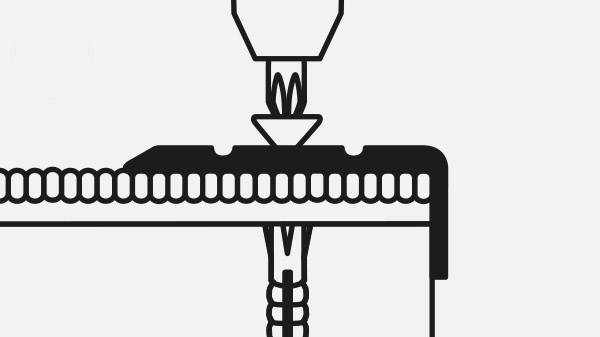

Cut the profile to the desired length. The countersunk drilled holes are transferred to the ground using a grain or a pencil. For mineral substrates, the marked holes are drilled and provided with a dowel after removing the drilling dust. Then the profile can be screwed on. Depending on the type of wood, wood subfloors can also be screwed directly through the screw holes.

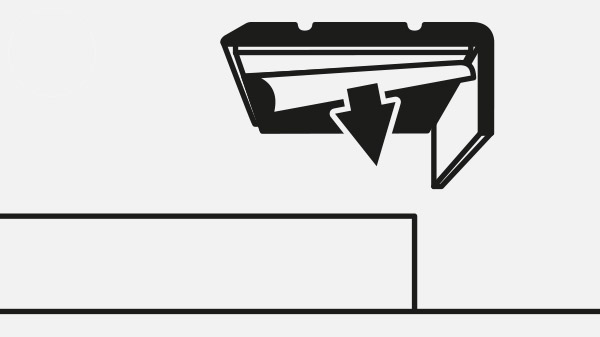

For auto-adhesive variants of the profiles, it must be ensured that the subfloor is stable and clean. Possibly the subfloor must be cleaned with a film-free cleaner. Under certain conditions, a bonding agent must be used to glue the profiles. Please note that a a loop can be pulled quickly when screwing or drilling in carpet floorings. If necessary, punch out the drill or screw hole beforehand.

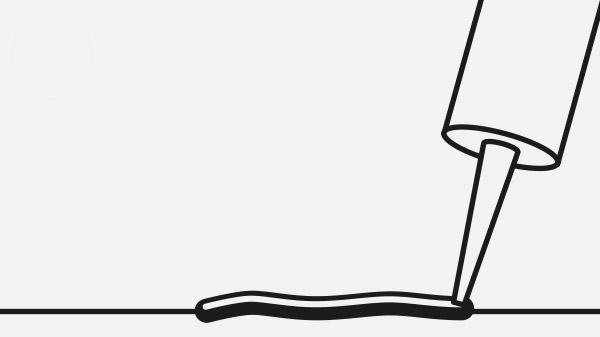

Unperforated, non-auto-adhesive profiles are always used when screwing to the subfloor is not possible or when the hole distance or diameter can only be clarified on site. Adhesives should be chosen so that they have a high initial tack and permanently withstand the dynamic forces. Hard-setting adhesives are not recommended. Please note the manufacturer’s instructions. If necessary, check the suitability of the adhesive in combination with metal and the subfloor. For dowels and screw fixings 5 mm dowels and screws with the dimensions 3.5 x 25 mm are usually used. Adjust the dowels and screws to your needs.