ECO-CLIP Profile system

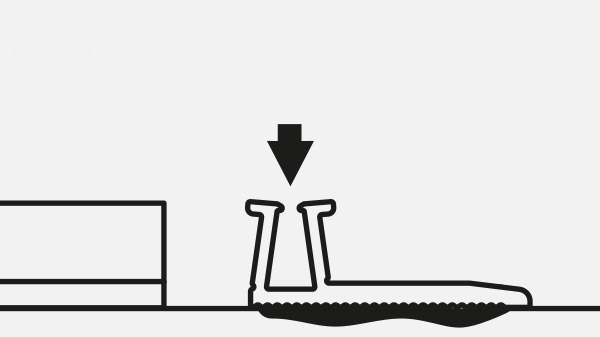

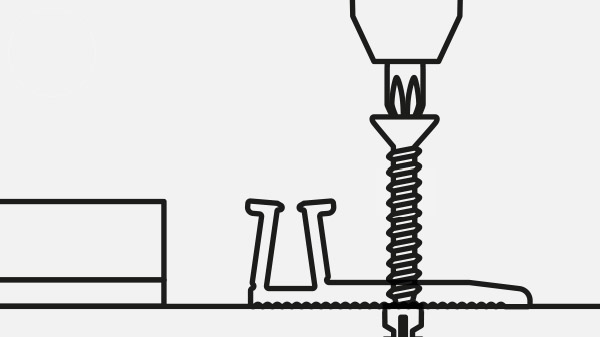

The base profile is preferably glued to the levelled surface according DIN EN 18 365 / DIN EN 18 202. We recommend commercially available SMP assembly adhesives e.g. Bostik Superfix or 2-component adhesive based on cast resin. When assembling an edge section it is important to clip in a piece of the top section to determine the correct distance of the base section to the wall.

The base section should be aligned in the adhesive bed before the adhesive sets. Make absolutely sure that you maintain a sufficient expansion joint between the floor covering and the profile. Remove excess glue before snapping the top profile into place. Please note that the adhesive has to be fully hardened.

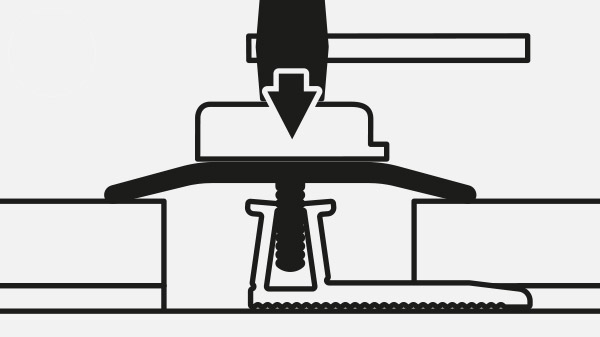

After laying the floor covering taking into account the expansion joint, clip on the top section into the guide groove of the base section with hand pressure until it has reached its end position. To take the final position, a blow can also be done with a soft rubber hammer. The connection section enables height compensation of up to 4 mm. The adaptation section allows a height compensation of max. 12 mm to 0 mm.